| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : HSTECH

Model Number : HS-GH350

Certification : CE

Place of Origin : China

MOQ : 1 set

Price : Negotiable

Payment Terms : T/T, Western Union, MoneyGram

Supply Ability : 100 sets per month

Delivery Time : 7~9 work days

Packaging Details : Wooden package

Product Name : Multi Function Vertical PCB buffer

Warranty : 1 Year

Control : Touch screen

PLC : MITSUBISHI

Relay Brand : Schneider

Optoelectronic Switch : OMRON

Material : Aluminum Alloy

Condition : New

Thickness : 0.6-4.0mm

Signal : SMEMA

Application : Electronic Assembly

Color : Silver

Control System : PLC

OEM/ODM : Available

Power Consumption : 200W

Power Supply : AC220V

Air Pressure : 4-6bar

Speed : 200-300pcs/min

Type : Automatic

Weight : 220/240KG

High Efficiency Multi Function Vertical Front Operation Intelligent SMT Production Line Automatic PCB Buffer

Technical Details

| Transport height | 910±20mm |

| Transportation direction | L~R, or R~L |

| Board cycle time | Approx 20 seconds |

| Maximum PCBs capacity | 20pcs or specify |

| Maximum load | 2kg/PCB |

| Track fixed side | Front side |

| Operation side | Front side |

| Indexing pitch | 20mm pitch or specify |

| Power supply | AC100-230V,1ph,300VA max |

| Air pressure | 4-6Bar |

| Air consumption | Max 10L/min |

| Signal | SMEMA |

Specification

| Model | HS-GH350 | HS-GH460 |

| Efficient PCB size | 50*50~450*350mm | 50*50~530*460mm |

| Machine dimension | 500*910*1600mm | 600*1020*1600mm |

| Weight | 150kg | 200kg |

Features

1. Use friendly soft touch LED membrane control panel.

2. FIFO,LIFO,and by pass operating modes.

3. Standard threshold signal to protect the boards in upstream reflow oven.

4. Control mode: PLC+button control or touch screen control.

5. Enclosed design ensure the safety operation.

6. Conveyor rail using special hardness treatment aluminum for long time usage and the strong PCB holding ability.

7. Smooth and precision width adjustment(lead screw).

8. Three color LED display and audible alarm working status.

9. Small machine footprint.

10. SMEMA compatible.

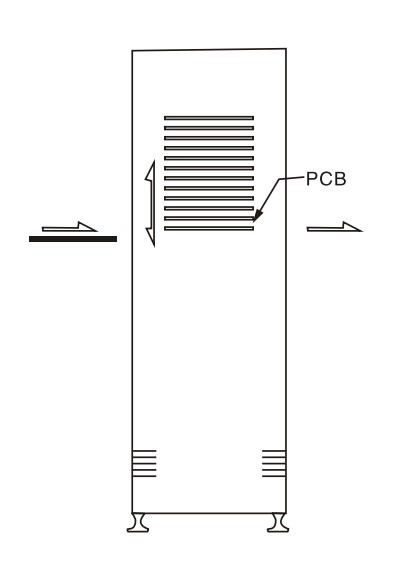

Machine drawing

Application

This vertical PCB buffer is designed to have the function as LIFO and by-pass functions, which can be located between SMT machines to improve the working efficiency by buffering.

About Packaging

|

|

High Efficiency Multi Function Vertical Front Operation Intelligent SMT Production Line Automatic PCB Buffer Images |